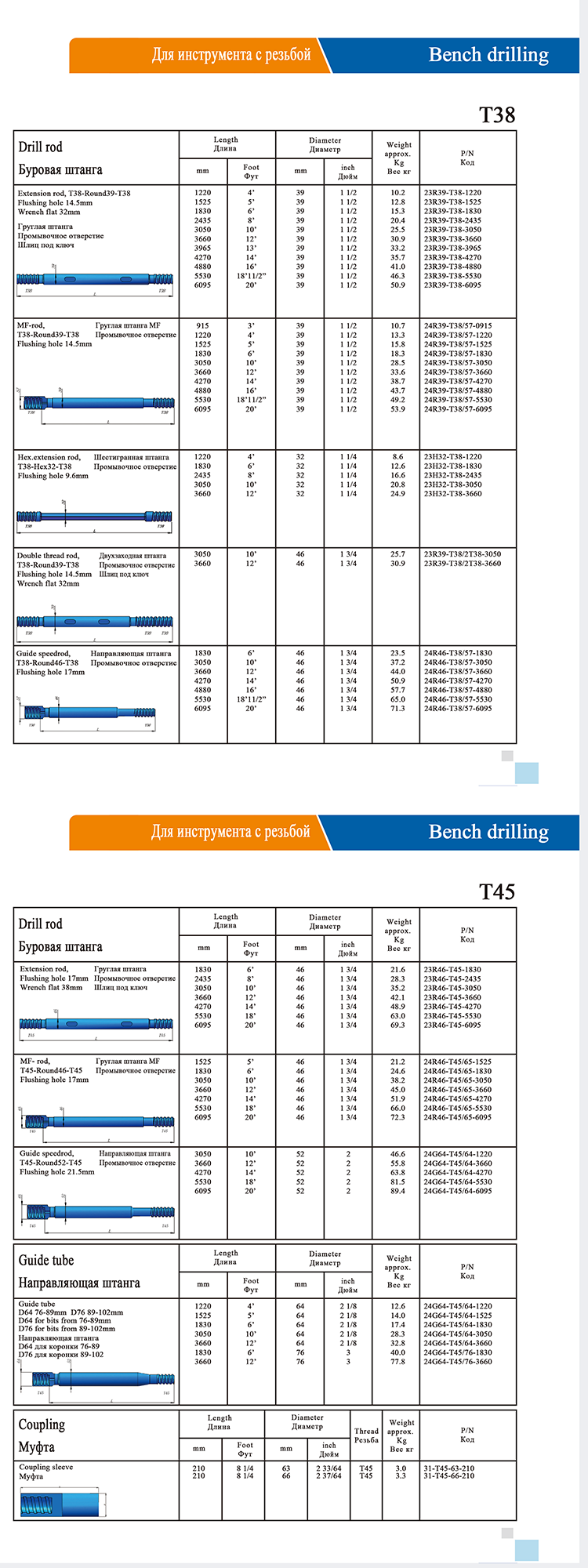

T38 T45 T51 lithupa tsa lebelo la ho phunya majoe

Litlhaloso tsa Drill Rod bakeng sa hydraulic, lisebelisoa tsa ho cheka hamore tse holimo

lintho tse bonahalang: Structural Alloy Steel

Kopo: Tunnel , Ho phatloha , Meepo , Ho rala likoari, ho qoelisoa, seliba sa metsi sa Indutrial, le Kaho ea Meaho.

Ho cheka ka Facedrilling le Bolting, Ho cheka Benche, Ho phunya tlhahiso, Ho cheka mekoti e telele

Mofuta oa likhoele:H22,R25,R28,R32,R35,R38,T38,T45,T51,GT60,ST58,ST68

Mofuta oa lere: Thupa e atolositsoeng, molamu oa Drifter, molamu oa MF, molamu oa MF Drifter, tube ea tataiso, molamu oa boro, tšepe e kopaneng, molamu oa sekoti oa lesoba

Mofuta oa 'mele: Mofuta oa hexagonal, mofuta o chitja

Bolelele ba molamu: 260mm ~ 6400mm

CustomDesign: Khoele, Diameter, Bolelele, 'Mala li ka etsoa ka mokhoa o ikhethileng

Foromo ea khokahanyo: mofuta oa khokahanyo ea khoele, mofuta oa khokahanyo ea lisekoere, mofuta oa khokahanyo ea hexagonal

Sekoti se bataletseng: Φ34.0mm, Φ42.0mm, Φ50.0mm

Konopo ea khoune: Φ63.5mm, Φ73.0mm, Φ89.0mm

Mofuta oa khokahano ea sekwere: F24, F.26, F30, F32

Mofuta oa khokahanyo ea hexagonal: B34, B35, B41, B45, B55, B41-B42.5, B48-B49

Sebaka sa kopo: E loketse kaho ea ho cheka mekoti e tebileng ka maemo a jeoloji ka holimo ho thata e mahareng.

Melemo ea lihlahisoa

'Mele o ka sehloohong oa phala ea ho phunya o entsoe ka phala ea tšepe ea boleng bo phahameng ba geological special alloy,' me motsoako oa phala ea ho phunya o entsoe ka tšepe ea boleng bo holimo ea alloy.E entsoe ka ho etsa khatello e phahameng, kalafo ea vacuum, welding ea likhohlano, le ho thatafatsa holim'a metsi ka kakaretso.Ts'ebetso ea likhoele e sebelisa lisebelisoa tse tsoetseng pele tse ikemetseng ho netefatsa hore e 'ngoe le e' ngoe e nepahetse ea sehlahisoa ka seng.E na le litšobotsi tsa matla a ho kobeha a phahameng, welding e tiileng le ts'ebetso e phahameng ea ho ntša slag.Ha ho bapisoa le lihlahisoa tse tšoanang, matla a mokhathala le matla a ho kuta li ntlafatsoa haholo.

Moralo o fapaneng oa sebopeho sa spiral blade o na le mefuta e mengata e fapaneng ea lits'ebetso bakeng sa ho cheka maemo a jeoloji.Moralo oa sebopeho sa lehare le phahameng la spiral le loketse bakeng sa kaho ea ho cheka sekoti se tebileng ka maemo a jeoloji ka holimo ho mahareng le a thata, 'me moralo oa sebopeho sa lehare le tlase le otlolohileng o loketse maemo a bonolo le a bonolo a jeoloji.Ho chekoa ha seam ea mashala le ho cheka metsi a khase.E na le litšobotsi tsa ho ntša slag e sebetsang hantle, sekhahla se phahameng sa ho phunya sekoti mme ha ho bonolo ho khomarela.